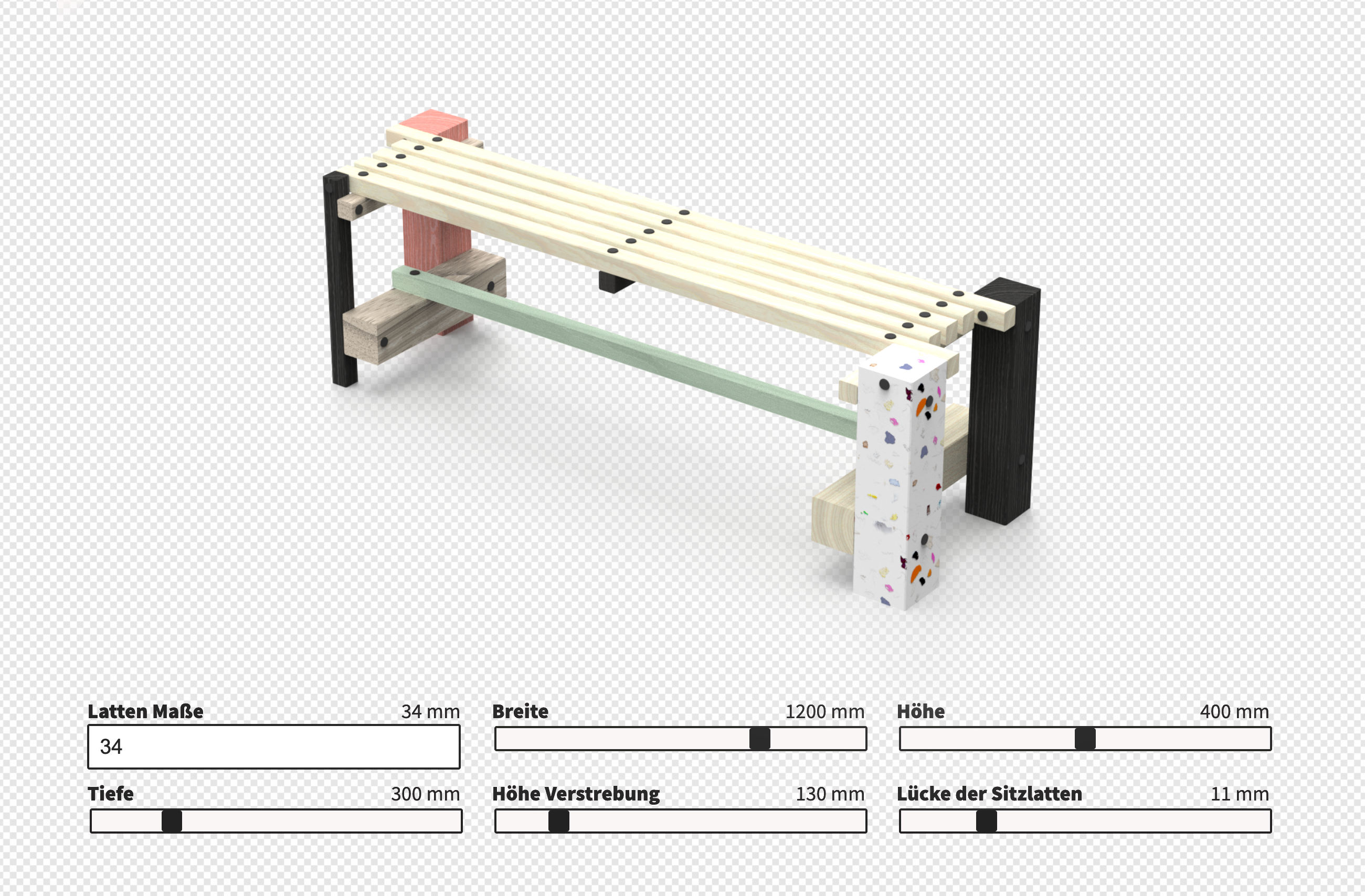

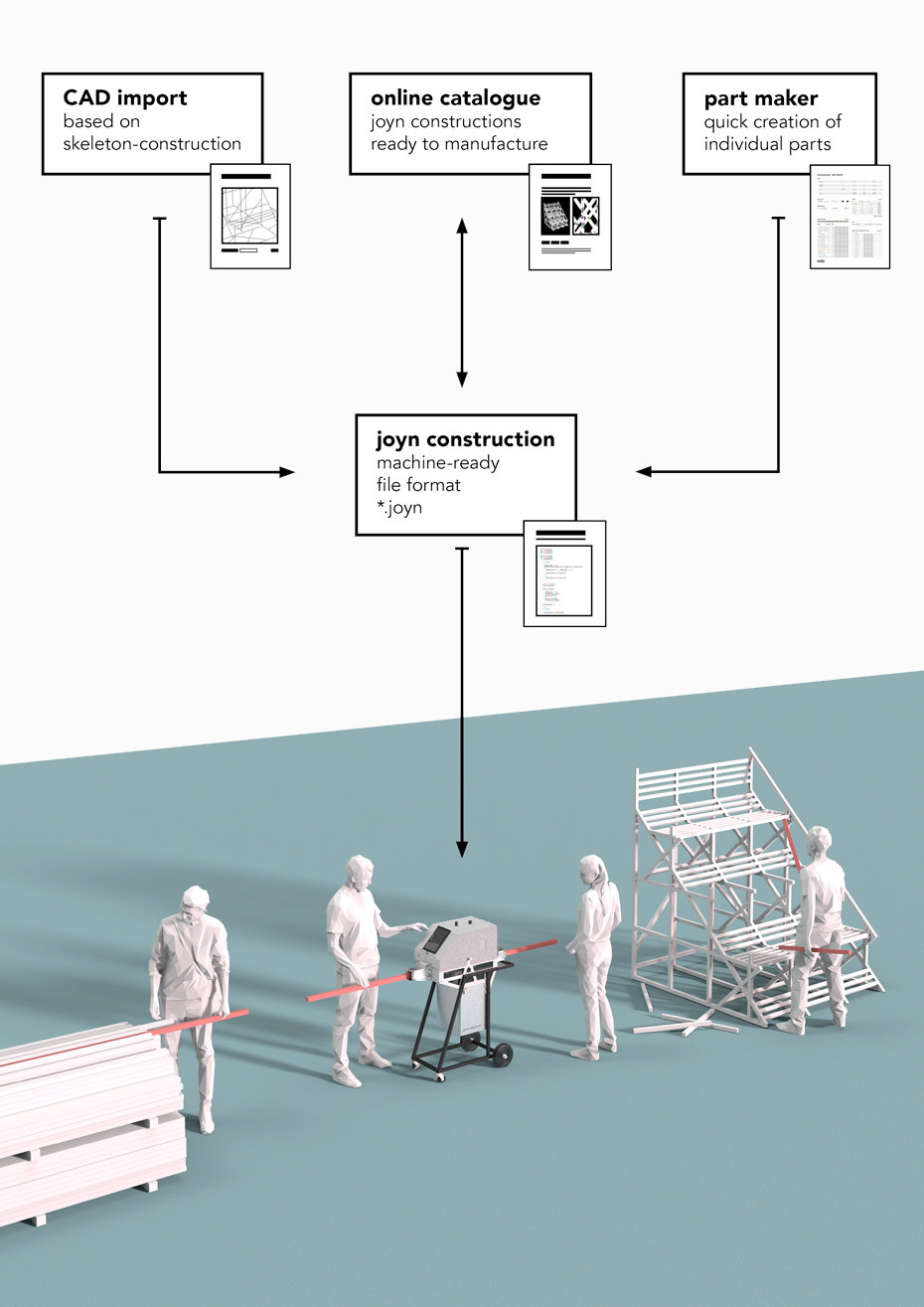

The JOYN MACHINE is following an “all-in-one concept” covering the entire production chain from designing a wooden structure, to processing the raw material (wooden slats), to manufacturing the wooden parts that can then be assembled into the designed structure.

The idea of providing one tool that combines all these skills is achieved by closely linking software and hardware components, but also by the construction of the hardware itself: With a weight of about 100 kg, JOYN MACHINE is portable. At the core, it is a three-axis milling machine with a rolling conveyor for the y-axis positioning the wooden slats, including mechatronic, automatic calibration. In practice this means that the user will take a wooden slat and “feed” it to the machine which then does all the rest.

The milling-engine has a power-output of 1 kw and can use milling-tools with an operating width from 6 to 12 mm. The machine is completely cased-in to protect the user from noise and it has a built-in solution for the extraction of waste using an external heavy-duty vacuum cleaner.

The machine uses a bespoke motion controller circuit board and generally features fully integrated electronics. On the software side, the focus is clearly on user-centricity and “app-like” interaction and the possibility to control the machine via a built-in tablet computer - including live video of the milling process from the inside of the the machine.

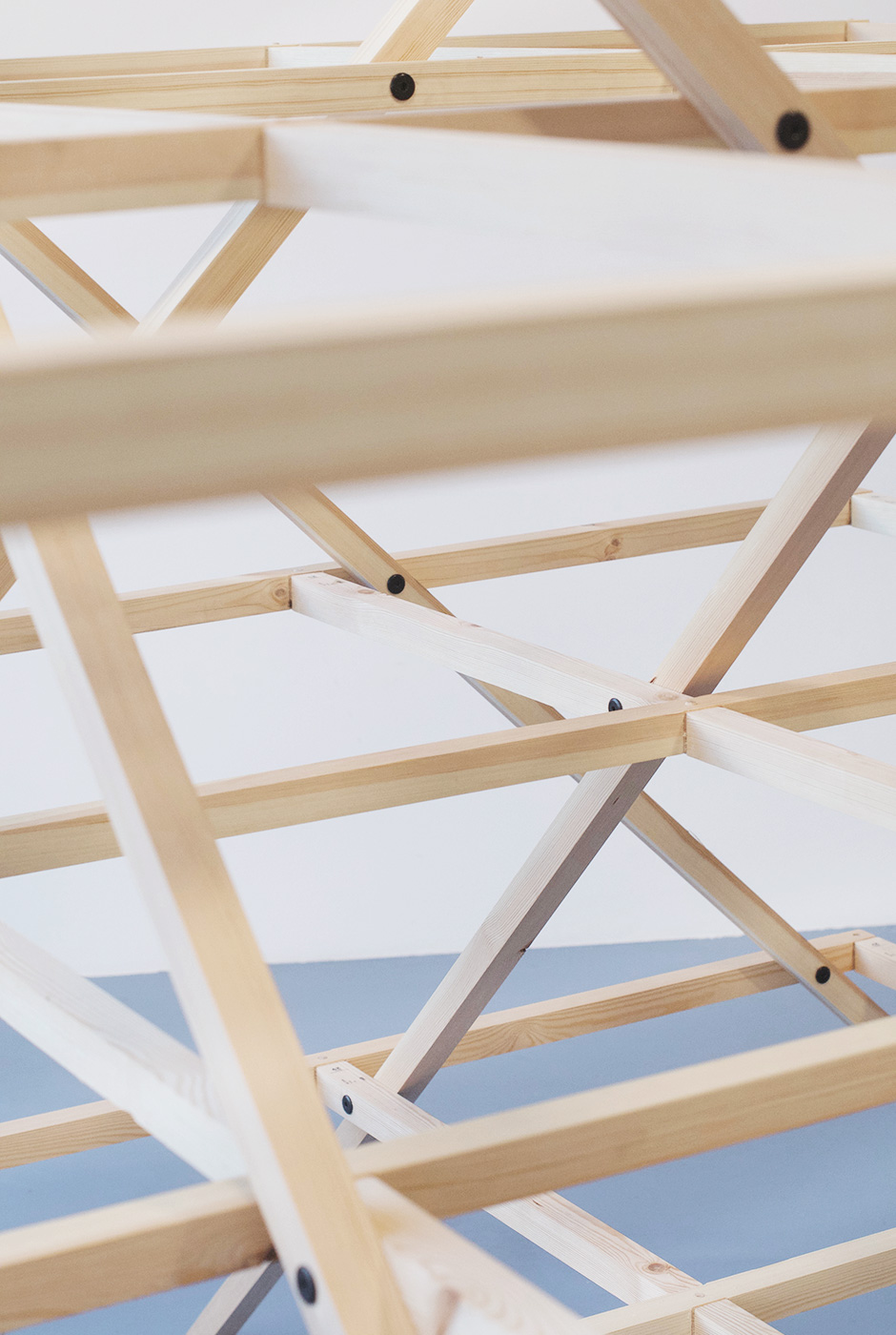

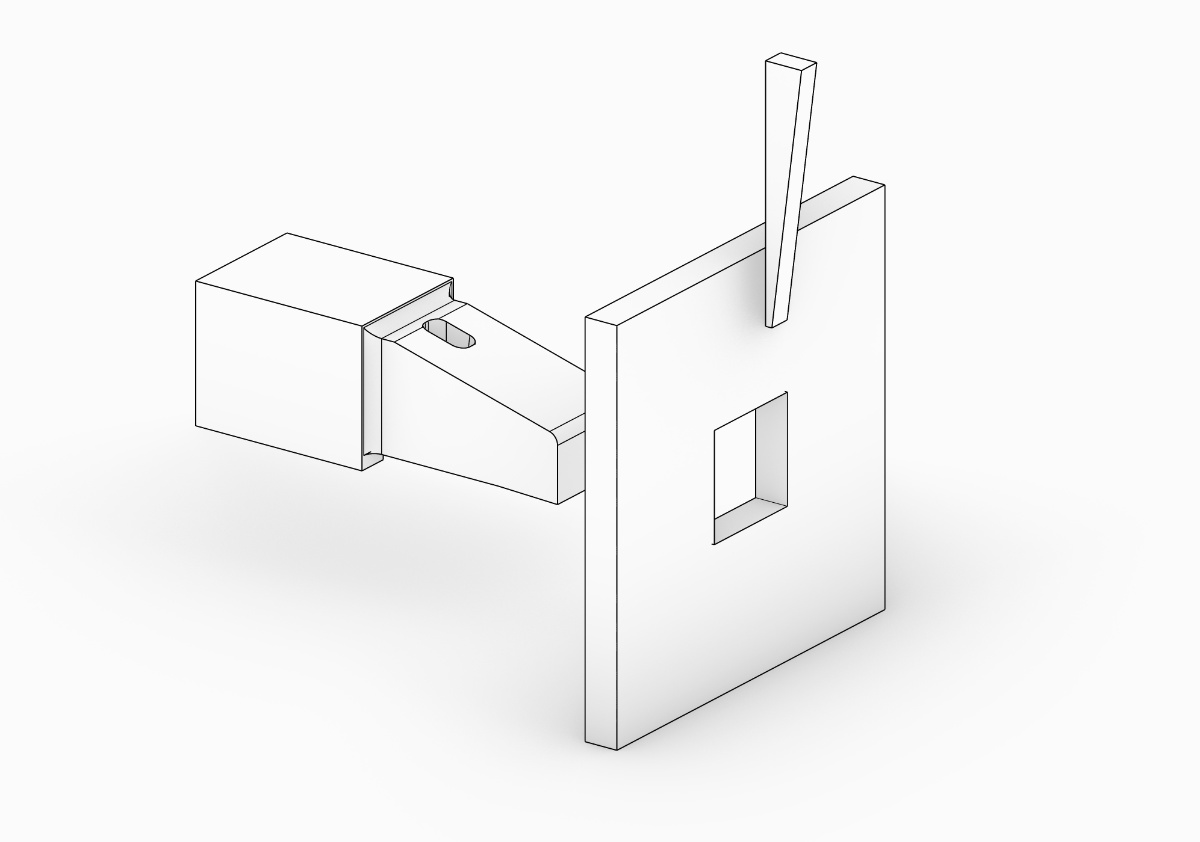

Joinery for non-destructive disassembling

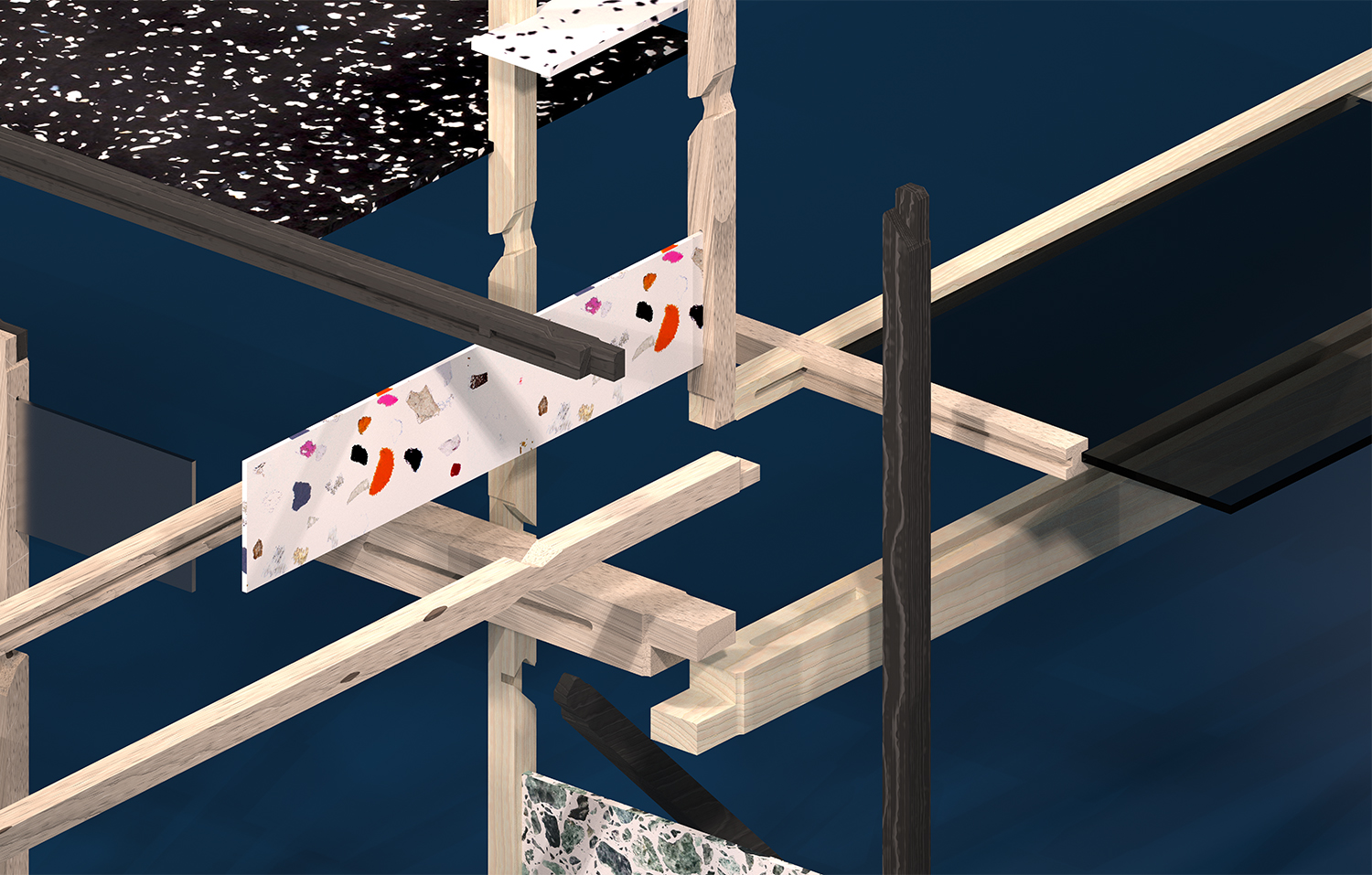

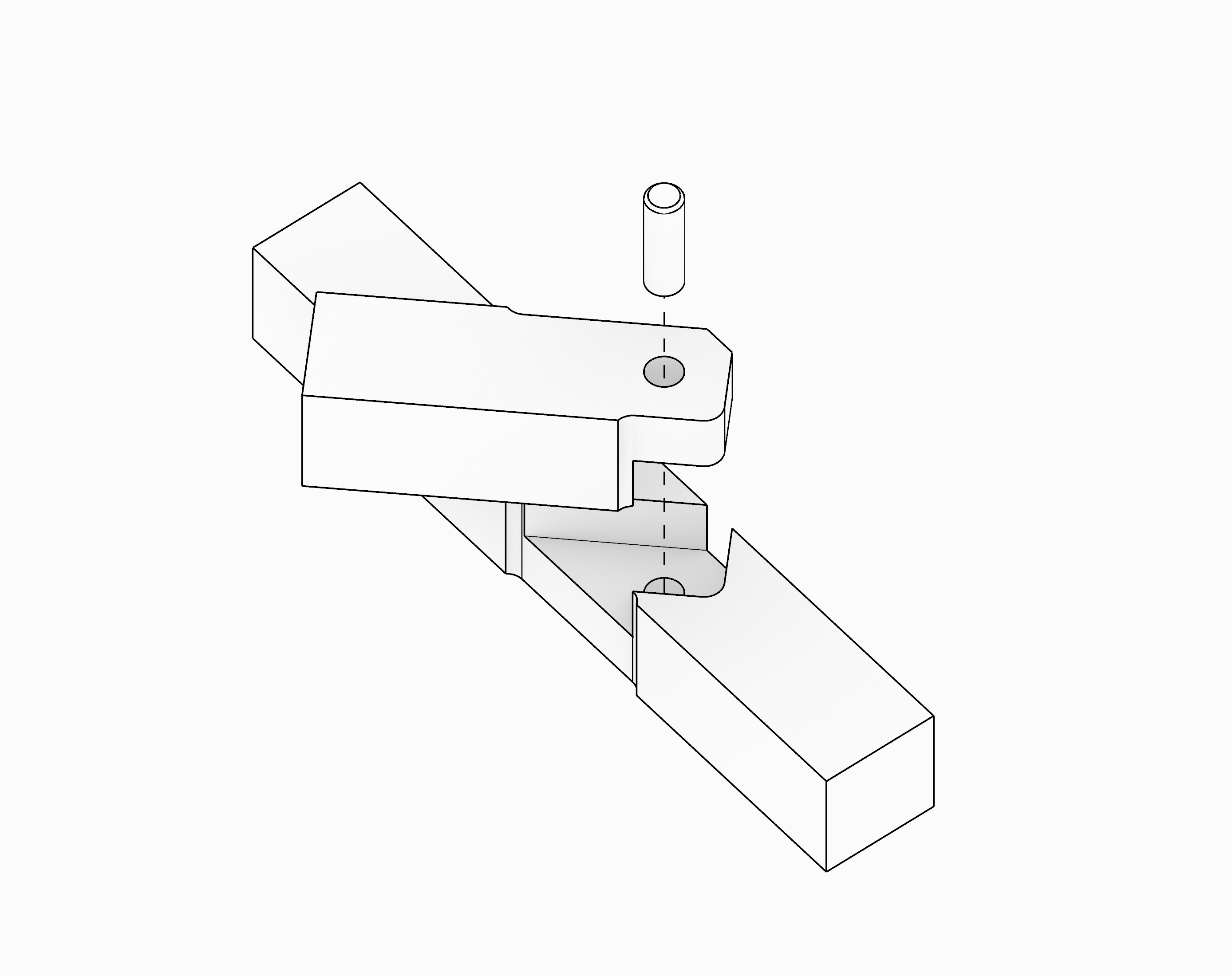

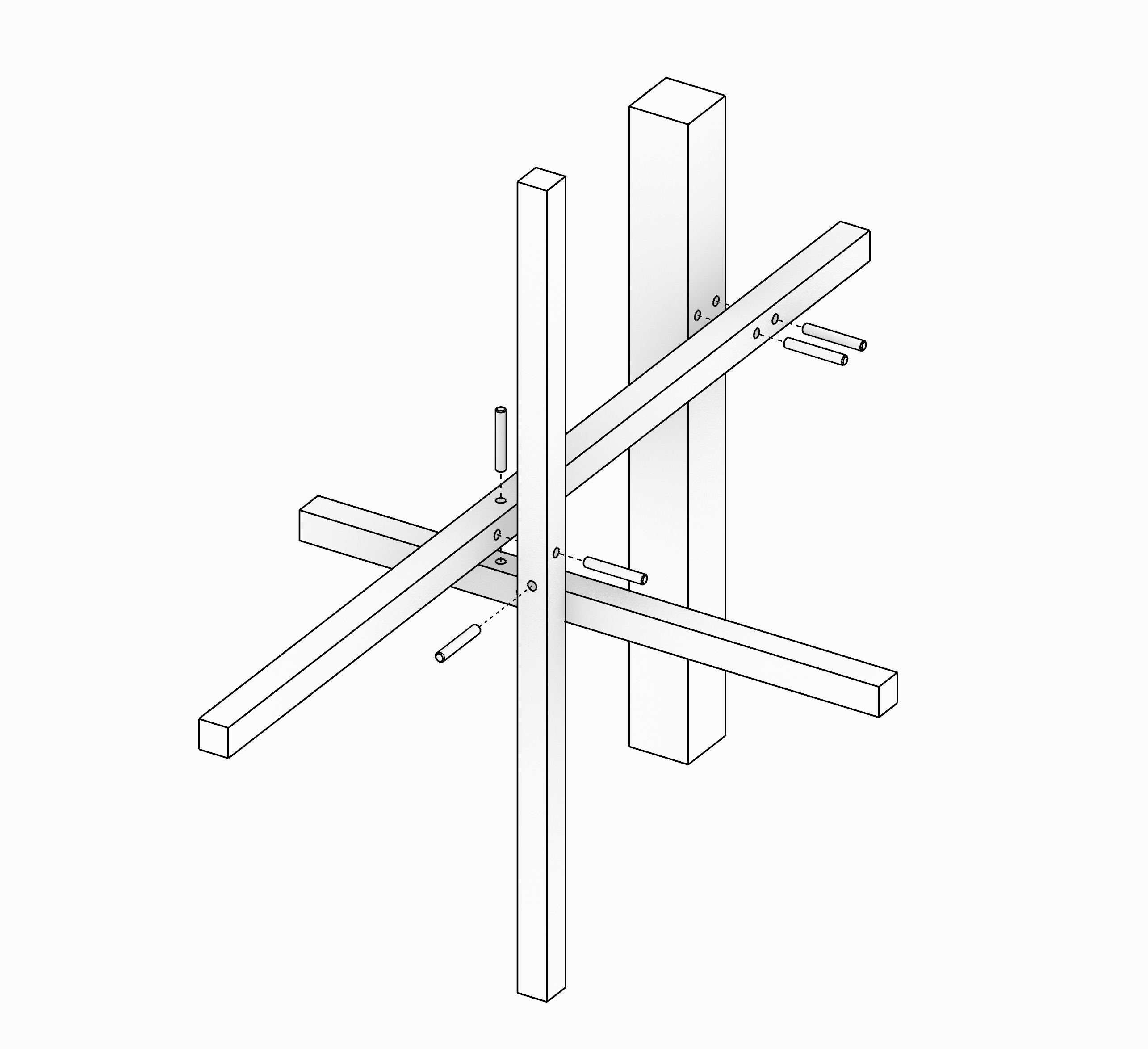

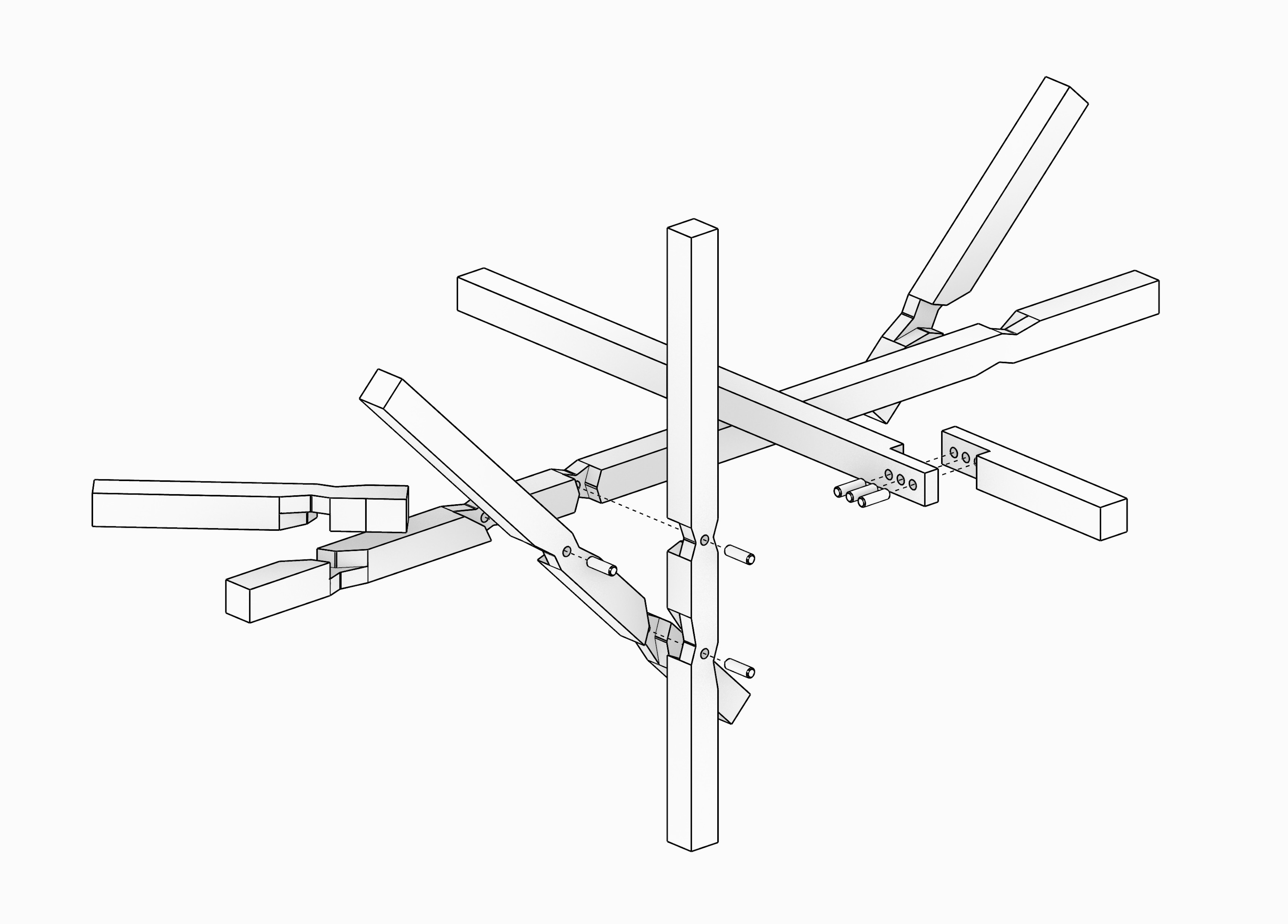

A key aspect of our approach is the use of joinery that does not require glue. This enables easy exchange of parts and complete dismantling of the constructions, promoting sustainability. Our joinery techniques include wood-to-wood connections like press fittings, pegs, wedges, and occasionally, we use metal connectors like bolts. Reducing to standardized materials with a square cross-section significantly increases the ease of recyclability. This flexibility ensures that our constructions are not only durable but also environmentally friendly, supporting a wide range of sustainability features.

Sustainability Concepts

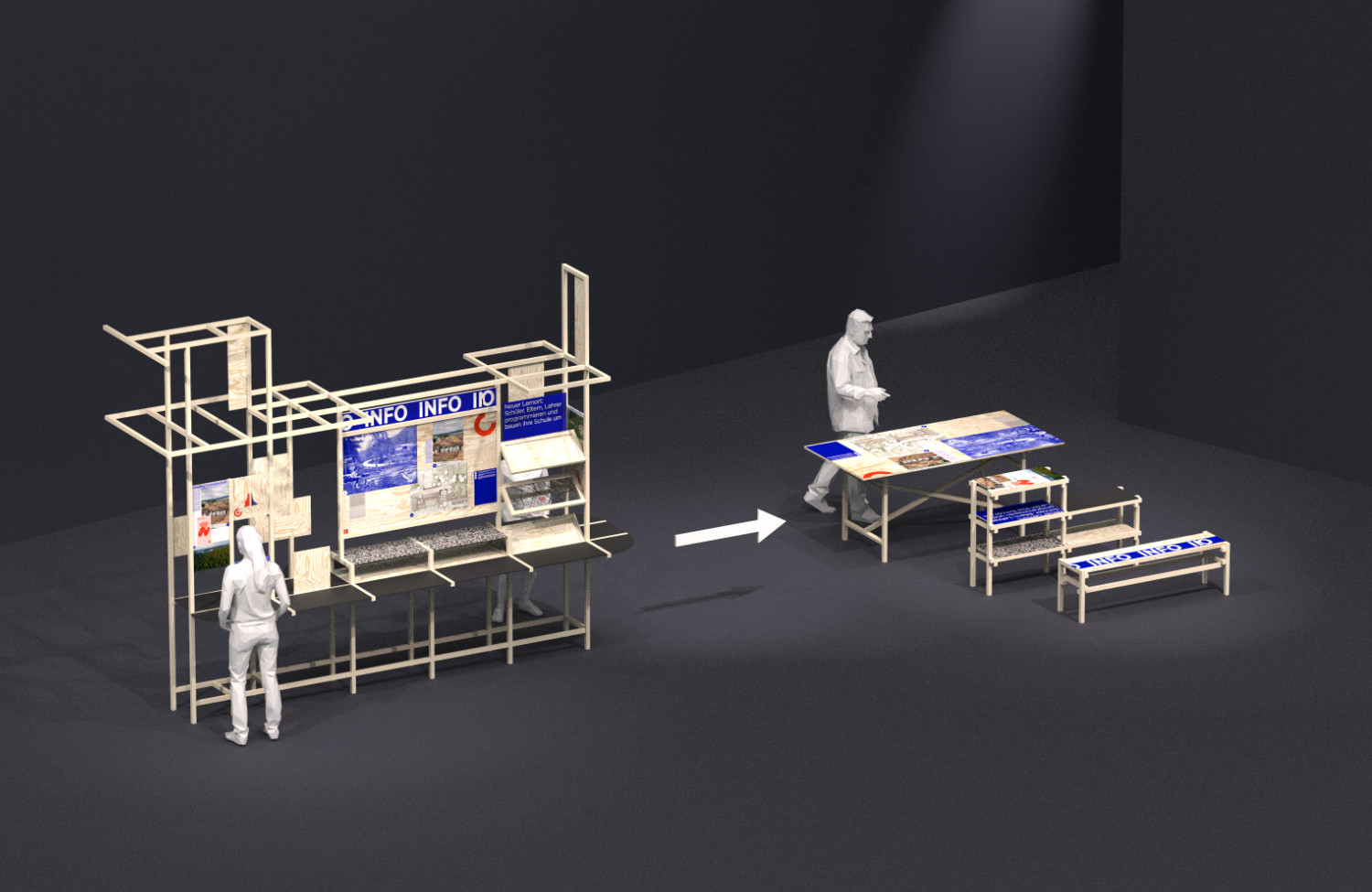

1. TRANSITION FORM DESIGN

A Sustainable Approach Using Custom-Made Wooden Parts with Dual Purpose

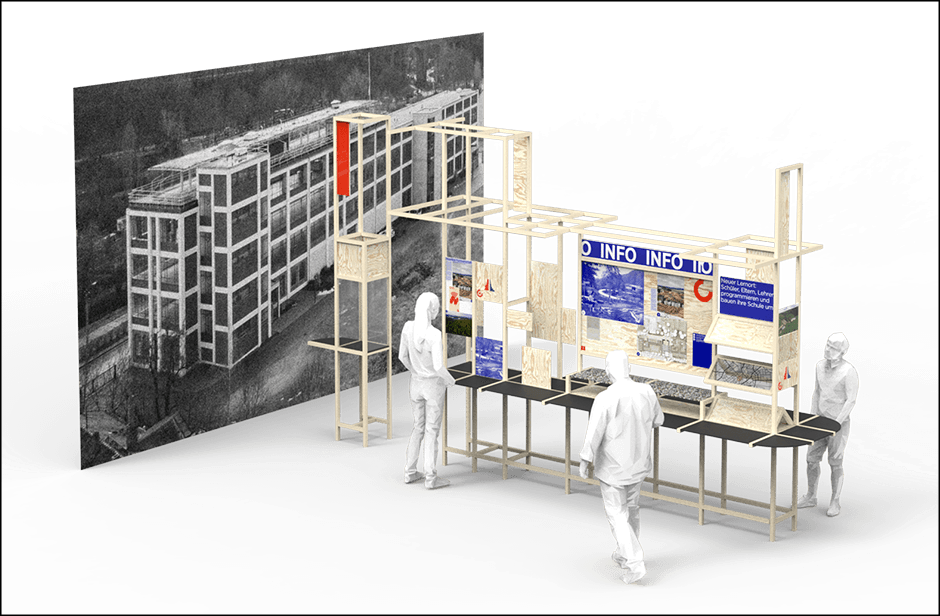

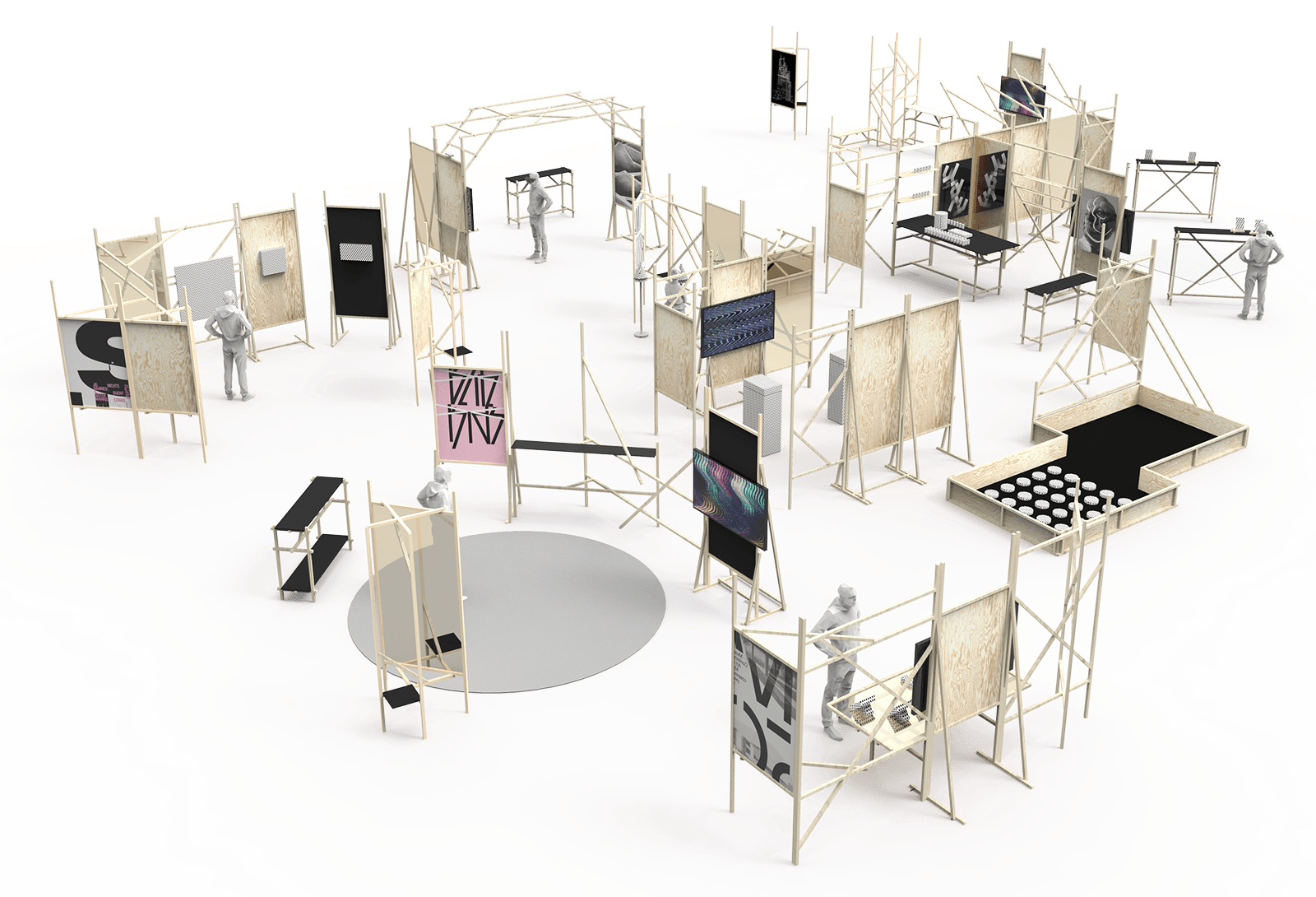

In the evolving field of architecture and interior design, sustainability is a critical consideration. Our innovative concept transition form design is following the idea of “Umbaukultur” from the building sector, and gives custom-made parts which are assembled with reversible techniques a dual purpose. This approach not only promotes sustainability but also emphasizes versatility and resource efficiency in design.

The Concept

Transition form design is a philosophy where the initial construction phase incorporates elements that will be repurposed in the future. In this context, custom-made parts are used to create a temporary structure, which is then disassembled and transformed into permanent furniture or other functional elements. Wooden press fittings, wood pegs or rarely metal screws make that possible. This methodology ensures that materials are not wasted and that the lifecycle of each component is extended, aligning with sustainable principles.

Application

Consider an exhibition space designed to be open for a short time period. Traditionally, such spaces are built with materials that may be discarded or underutilized after the exhibition ends. However, with the transition form design approach, the wooden parts used to create the exhibition's architecture are designed with a second life in mind. For instance, the wooden panels, beams, and supports that shape the exhibition's interior can be later reconfigured into long time use constructions (e.g. tables and benches).

This concept of dual-purpose design means that the initial construction may appear unconventional or a bit "off" because the form is dictated by the future use of the materials. The architecture is a means to an end, where the end goal is the creation of durable, long-lasting furniture. The aesthetic of the exhibition space, therefore, reflects this forward-thinking approach, showcasing a raw and functional beauty that hints at its future transformation.

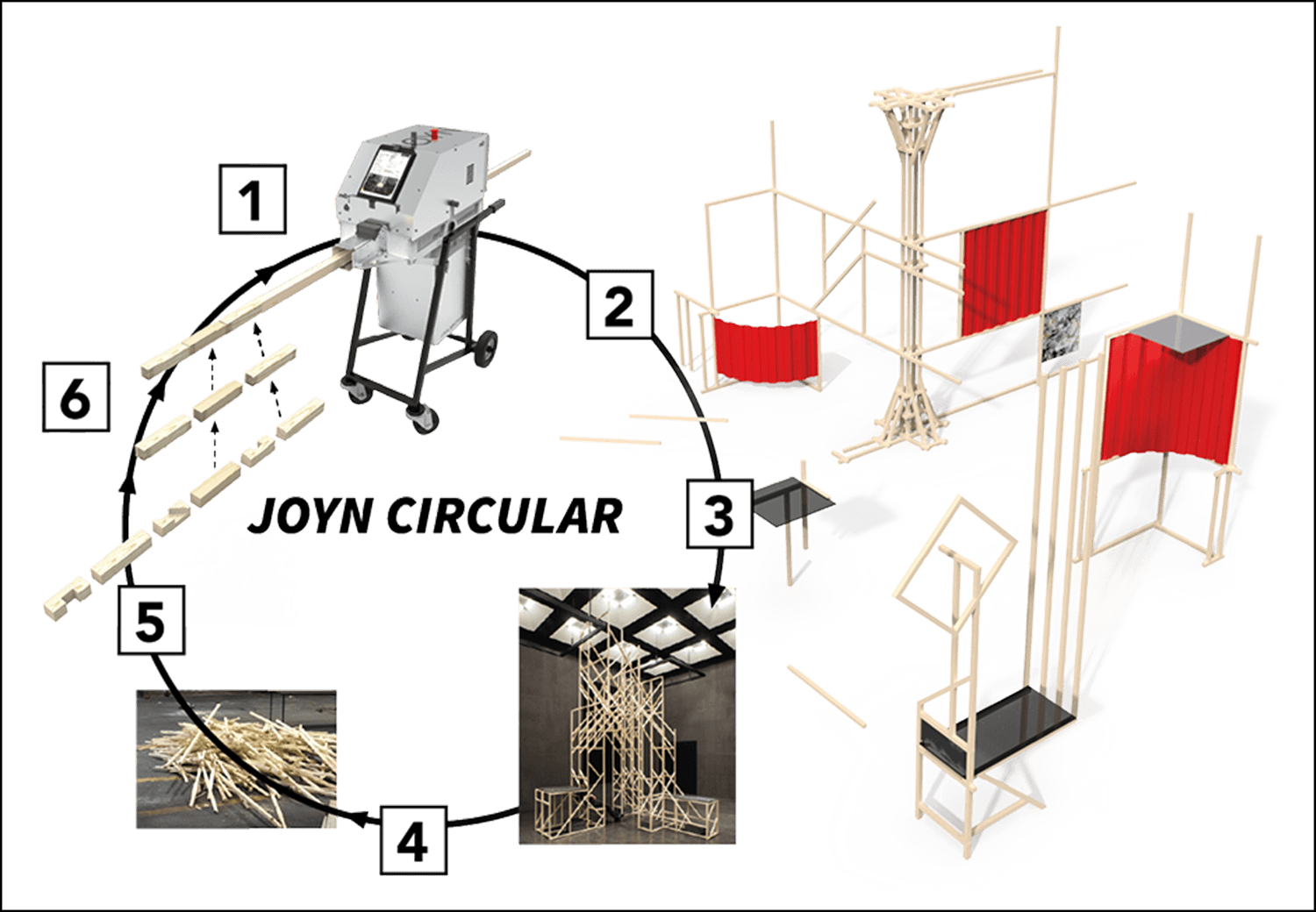

2. JOYN CIRCULAR

A Sustainable Approach to Recycling Material Using Finger Joint Technique

A exhibition architecture by studio milz can be easily disassembled due to glue-free wood connections and enables damage-free disassembly and the recovery of all used materials. In the pursuit of sustainability, refurbishing wooden slats from dismantled constructions offers a compelling solution.

The core of this sustainability concept lies in the dismantling of wooden constructions. The focus is on wooden slats, which form the framework of these structures. After dismantling, the sections of the slats containing pockets for wooden joinery are cut out. The remaining clean pieces are then glued together with Finger Joints (Keilzinkenverleimung). This method creates new, long slats that are ready for the next project.

1.Design and Production → 2.Assembly of milled wooden kits → 3.Final construction → 4.Deconstruction of outdated projects → 5.Return to the recycling cycle → 6a.Extraction of undamaged slat pieces → 6b.glued finger-jointing → 6c.manufacturing of solid structural timber ("Konstruktionsvollholz" short: KVH)